Advantages of Driven Piles

Cast iron screw piles were used extensively throughout the uk. Micropiles as Per Based.

Driven Pile Driven Pile Foundation Complete Guide

Unique Business Opportunity - Team with a proven industry leader.

. Pile is a column of material driven by a piledriver. Suction caissons also referred to as suction anchors suction piles or suction buckets are a form of fixed platform anchor in the form of an open bottomed tube embedded in the sediment and sealed at the top while in use so that lifting forces generate a pressure differential that holds the caisson down. If sealable joints are.

The types of pile foundation are end-bearing piles friction piles compaction piles anchor piles tension or uplift piles sheet and batter piles etc. Pictures automatically update to show results based on current settings. Displacement piles are driven or vibrated into the bottom there by displacing the adjacent soil sideways during the inauguration.

One of Agiles big advantages over the traditional approach is that it focuses on data-driven forecasting rather than estimating based on gut feelings. The piles are either driven or more commonly vibrated to the necessary depth. 5 Advantages and Disadvantages of Soldier Pile Walls Upcoming Workshop.

What Sets Us Apart. Once the length of the pile is decided it is difficult to increase or decrease the length of the pile afterward. Solutions for Geotechnical Engineering Professionals.

Supported types of piles. Fast installation cut schedules substantially. QuayWalls - The Ultimate Quay Walls Design Software DeepEX 2021 - The New Version is Here Design Single Piles Pile Groups Rafts.

The method is known as Monte Carlo Simulations. This allows a continuous operation and allows the following trades access to the initial caps sooner. The piles can be loaded immediately after it is driven up to the required length.

Reinforcing in auger piles. Helical piles can also be installed at batter angles where the piles provide both lateral and vertical resistance. They have a number of advantages over conventional offshore foundations.

Helical piles in a tie-back system Perko 2009 Helical piles can also be installed in a tie-back system where one pile is installed at an angle to provide lateral resistance while another is installed vertically to provide vertical resistance Perko 2009. Since the steel is readily available construction can be done quite easily. These are the most economic form of deep foundation and can also be driven underwater.

Design of Deep Foundations Helical Piles The Future is Here. In recent years groynes have now been made from steel bars and concrete among others materials as well as being made to. This includes permanent sheet pile basements all forms of temporary sheet piling works and a wide variety of sheet pile installation projects.

Needs heavy and expensive equipment to. For greater depths additional piles are simply welded to the piles already inserted into the ground. Add and edit unlimited images from the analysis.

Interlocking sheet piles typically made of steel are simply inserted into the ground one by one. Bored pile also called drilled shaft is a type of reinforced-concrete foundation that supports structures with heavy vertical loadsA bored pile is a cast-in-place concrete pile meaning the pile is cast on the construction siteThis differs from other concrete pile foundations like spun pile and reinforced concrete square pile foundations which use precast concrete piles. GEO5 saves your time.

See All of Our Advantages. The program GEO5 Pile considers following pilling technique types. This article details the practices used in this methodology.

Teaming with HELI-PILE as an Installing. It has a head office in Preston Lancashire and a regional office in London and specialises in all aspects of driven sheet piling. Extreme programming XP is an agile software development methodology used to implement software projects.

Frequently a protective steel cap or mandrel is utilised to protect the pile head and ensure more even distribution on the end of the sheet pile of the driving load. Vinyl Sheet Piles can either be driven jetted in or dug and then installed. Quick safe and efficient installation.

Pier has a footing. Further steel piles such as micro piles can be used to support heavy loads applied from bridges and other types can be used to support medium level loads. Pier is inserted down to the bedrock.

Screw pile foundations were introduced as a practical foundation system by alexander mitchell 17801868 an irish builder and brick manufacturer. The methods of driving piles over water along with their economy and suitable working condition are discussed. Pedretti et al 2012.

Pre-cast piles can be driven under the water. In 1867 the first concrete groyne was built near East Street and it is a free promenade of 195 feet 59 meters in length. These piles need to be driven over water.

Auger cast pile grout is readily available locally and is inexpensive when compared to steel piles. Oldest type of groyne is made entirely from wood piles or staves. Add Buildings from Google Maps.

Driven piles however can typically be installed adjacent to each other immediately allowing each cap to be completed prior to moving to the next cap. These piles are resistant to the biological and chemical action from the subsoil. They can easily bear high tension loads.

Lower cost than driven or drilled piles. Install in any weather. Advantages Pearlman 1999.

Concrete or grout is pumped through the hollow stem maintaining static head pressure to fill the cylindrical cavity created as the auger is slowly removed. There are different types of driven piles constructed from the steel. Their uses included supporting lighthouse foundation frames as well as pleasure piers across the uk.

Disadvantages of Pre-cast Piles. Driving is the most frequent method for installation of vinyl sheet piles. The main issue with the steel driven piles is the corrosion.

They are difficult to mobilize. Caisson is putting a box into underwater and pouring it with concrete. The grout pressure and volume must be carefully controlled to construct a continuous pile without defects.

Extreme programming has 12 practices grouped into four areas derived from the best practices of software engineering. Piles are used as a foundation for various marine structures such as wharves and jetties. CFA piles are constructed by rotating a hollow stem continuous flight auger into the soil to a designed depth.

Eliminate or minimize concrete use. This can be done by relying on historical data that is run through many random simulations to forecast a probable future outcome. Replacement piles are constructed within a formerly drilled borehole thus restoring the excavated ground.

Under some conditions an excavator can be used to provide the necesssary. Sheet Piling UK Ltd is one of the United Kingdoms leading driven steel sheet piling contractors. Over 25 such piers were constructed during the 19th century.

1 minuteVarious methods have been developed to drive piles over water. In the 1880s they were still used extensively in Britain. Pre cast concrete piles have the ability to withstand high pressure vertical loads.

Pile Foundations Types Of Piles Cassions Understand Building Construction

Three Main Pile Types Pile Steel Concrete

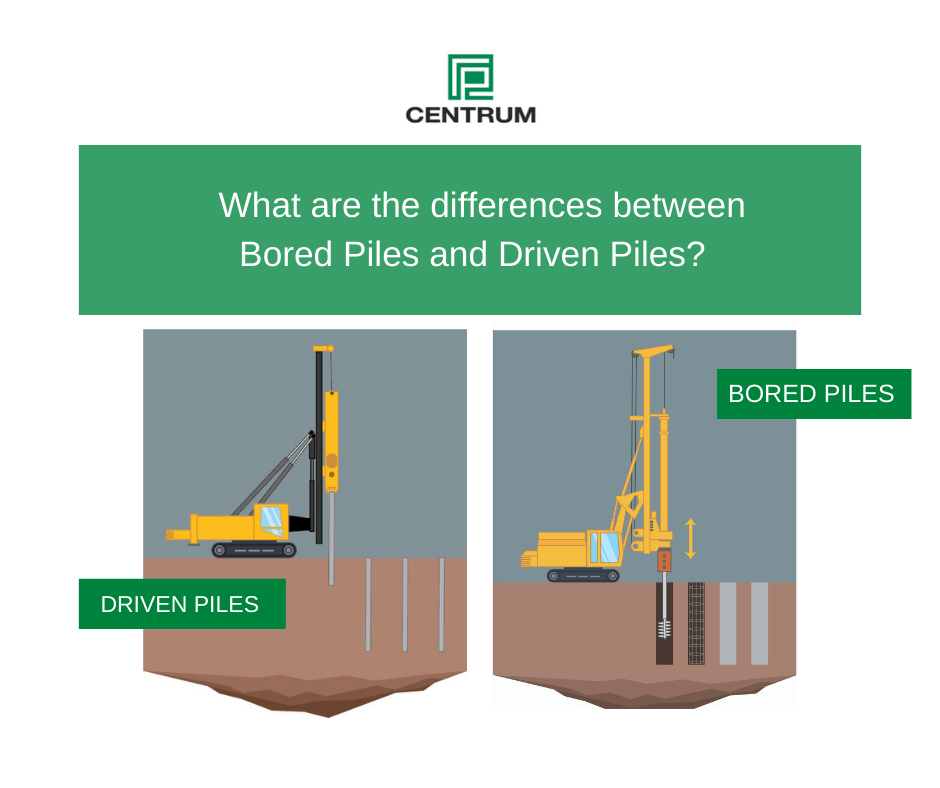

What Are The Differences Between Bored Piles And Driven Piles Centrum Pile Ltd

Benefits Of Driven Piles Pile Driving Contractors Association

Comments

Post a Comment